Steel Connections

The type of steel connection you choose will depend upon the nature of the connecting elements. If you are unsure which connection would be best for your building needs, B & S Steel Supply will be happy to offer free, impartial advice. Standard connection sizes are as seen below; alternatively, please get in touch for custom orders.

Our easily welded mild steel connections are available in the sizes shown below. Alternatively, request a custom size.

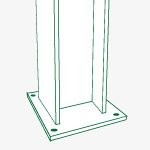

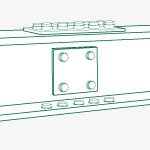

Base plate is commonly used for supporting a column protruding from a concrete pad or foundation. It is essential to leave a gap of between 20 and 30mm between steel plates and concrete to ensure stability and longevity. The remaining gap will need to be filled; this is achieved by packing a dry mixture of concrete into the available space.

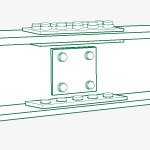

Forming part of the end plate connection, an end plate is used to join a column to a flange or to another beam.

An end plate connection joins a column to a beam, a flange, or another beam. It is a common element of any build.

A moment connection is frequently used for sections which are required to withstand a high level of stress for a ‘moment’, such as when a wall is replaced with a box frame and needs to withstand high pressures from all sides.

A cleat is used to bolt a beam into the side of an adjacent beam. Cleats are made of angle sections bolted to both beams. If only one side needs bolting, only one cleat will be required, and it is often a more desirable method than bolting.

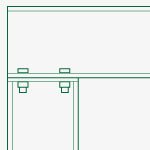

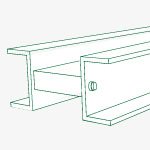

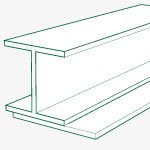

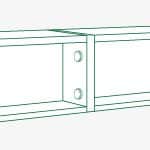

When projects are struggling for height, for instance in basements and lofts, it is often preferable to replace a deep beam with two smaller beams. However, to ensure stability and resistance to buckling, these beams need to be bolted together; this is where a spacer is used, and it is usually welded to one of the beams. The bolts are typically 600 mm apart from each other.

When a cavity wall needs to be supported above an opening, two PFCs can be bolted together back to back, with a spacer in between, to give the walls extra strength. The gap between the sections matches the width of the cavity, and the spacing between the bolts is 600 mm centre to centre.

The 90 degree crank is similar to a typical crank, except it has two kinks. The top member is horizontal and the bottom vertical. Cranked beams are frequently used to support heavy weight structures such as rooms, requiring the angle of the middle members to follow the pitch of the roof. Full penetration welds must be used with these connections to ensure successful carriage of the load.

The 90 degree kink is a two section connection welded together. Commonly used for brackets or for the support of a column where a bolted connection cannot be used.

Occasionally, a single kink following the pitch of a roof is adequate to support it without the need of an additional vertical column.

Very similar to the kink angle, the kink with plate simply has an additional plate between the two sections. Usually used when the pieces joining together are of different sizes.

As the name suggests, this horizontal beam has a vertical section welded at 90 degrees – similar to that of a dog leg. This beam is often used to support staircases.

Gussets are usually used to support the outer edge of a bottom plate welded to a beam. A gusset uses a triangular plate to provide additional stiffness to a structure.

The bottom plate is added to a beam to support timber joists or brickwork. The plate is stitch welded to the beam and can be offset so that the brickwork or timber is sufficiently supported.

Often used for door openings in a cavity wall, a top plate is added when the size of the required beam is smaller than the wall it carries.

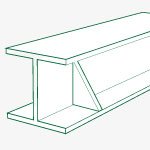

A stiffner will provide additional stability by connecting flanges and the web. It prevents the web from buckling by adding stiffness.

Usually used when welded to hollow column sections so they can be anchored to walls. They are generally used every 6cms in a staggered formation.

Holes are drilled in column flanges to anchor them to walls as an alternative to welding tabs. They are generally used every 6cms in a staggered formation.

To enable timber joists to be fixed to both sides of a beam, holes are drilled in the web. Hangers can then be fixed to the joists, allowing floor joists to be spanned from it.

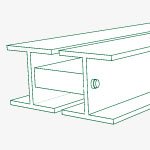

When a beam is too long or too heavy to install safely, a splice will be required. If a beam spans two walls, a splice will assist during the installation – otherwise a large section of the wall will have to be temporarily removed. A general rule is that the flange plate must be at least the same thickness as the beam’s flange. The same rule applies to web plates.

High strength friction gip bolts may be required, in which case the beam ends and splice plates require a primer. Primed bolts are expensive so we recommend requesting a redesign by your structural engineer to enable you to use the normal 8.8 grade bolts.

Structural engineers may require additional inner flange plates to be attached to the splice connection.

The A3 type splice is not a full strength connection, so it should only be used to align two sections. The A3 needs additional support via a column or pad stone.

If height is limited the regular splices of A1 and A2 can add up to 1cm to the total depth of the beam. If this is not a viable option, a B1 splice is recommended, although this too requires additional support because it is not a full splice.

Gallow brackets have been used to support chimney breasts for many years. However, many local authorities no longer allow them to be used. If your planning department advises that these are not permitted, then you will need to use a full steel beam structure instead.

We deliver all over london and the south east of England daily